Shearing & Cut to SizeOur professionals are experts in providing metal fabrication and shearing services. Our shears are highly advanced and thus we can create the metals of almost any length or width. At Contour Machine, we offer numerous shearing services to our customers and can handle numerous components of specific sizes as given by the customers. |

Shearing & Cut to Size |

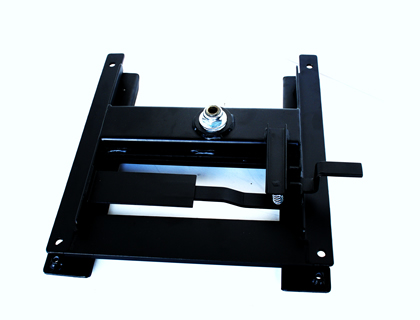

Sub-AssemblyOur clients can avail from us Sheet Metal Press & Sub Assembly Components that are widely used on various industries . Conform to international quality norms, our components are manufactured using high grade raw material such as steel & other alloys, and available in various designs at industry leading prices to fulfill the diverse needs of our customers. |

Sub Assembly |

Laser CuttingIn Contour Machine Ltd. we provide one of the best production Laser Cutting Technology, which enables us of easier workholding and reduced contamination of workpiece in all of our product |

Laser Cutting |

PolishingWhether to enhance and restore the looks of certain metal parts or object on cars and other vehicles, handrails, cookware, kitchenware, and architectural metal and any other metal product, We have the best metal polishing solution for you. |

Polishing |

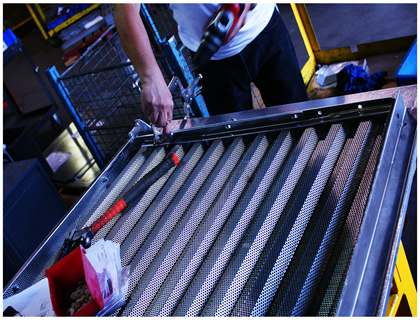

PunchingPunching is a metal forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. We have one of the most cost effective process of making sheet metal from average to high fabrication. |

Punching |

Spot WeldingThis is a process in which contacting metal surfaces are joined by the heat obtained from resistance to electric current. Work-pieces are held together under pressure exerted by electrodes. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. |

Spot Welding |

FormingThe advantage of the metal forming process is that the metal comes out with other abilities which are usually stronger after it has taken shape. |

Forming |

WeldingTwo most common welding processes we use include TIG, an acronym for Tungsten Inert Gas welding and MIG, an acronym for Metal Inert Gas welding. TIG welding is a slower process than MIG, but it produces a more precise weld and can be used at lower amperages for thinner metal and can even be used on exotic metals. |

Welding (Tig, Mig, Stick & Stud) |